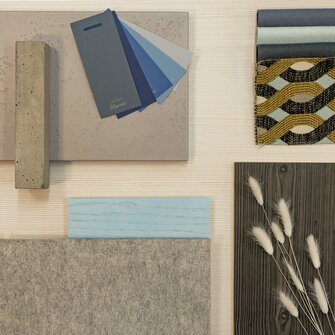

Updates from the ADLER world of colours

Learn more about innovations, new products and the latest from ADLER.

An error occurred

© by adler-lacke.com