Excimer coatings – UV coatings for extremely matt surfaces

An interesting alternative to the classical matting processes is the physical matting with so-called excimer UV rays.

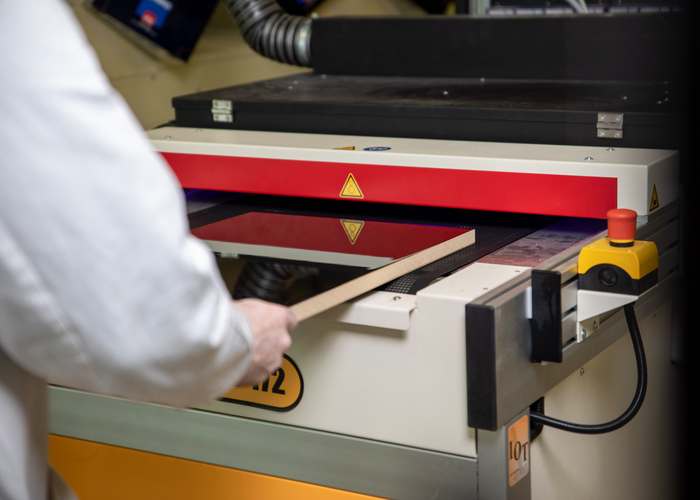

The EXCIMER process

The EXCIMER process In this new method, the liquid UV-curing excimer varnish "Innolux Topcoat EXC" applied by rolling is irradiated with short-wave UV light (172 nm) under exclusion of oxygen. This leads to a superficial polymerisation, which causes a volume shrinkage, which in turn manifests itself in surface folds of varying degrees. This deformed "skin" leads to a diffuse reflection of the light, which we perceive as a matt effect. To completely cure the coating layer, it is immediately followed by irradiation with a UV dryer.

ADVANTAGES OF EXCIMER TECHNOLOGY AT A GLANCE

- Dull matt gloss levels without matting agent (gloss levels from 3 to 20)

- Extremely scratch and abrasion resistant coated surfaces

- Increased surface hardness

- Outstanding chemical resistance

- Soft touch effect

- Anti-fingerprint effect

- Perfect reproducibility

- Pleasant feel

- No solvents

Improves efficiency in the coating process, optimises series production, saves time and costs

Innolux TOPCOAT EXC is a latest generation excimer coating – for dull matt surfaces with anti-fingerprint properties. We will be happy to advise you on the excimer technology without obligation.

OUR SERVICES

Together with our industrial partners, we adapt the entire application including plant configuration to your needs. Before commissioning, we carry out tests of the entire system (coating, substrate, excimer radiators and UV curing).

Industrial partner plants:

- IOT Innovative Oberflächentechnologien GmbH

- IST METZ GmbH

- GIARDINA Group

© by adler-lacke.com